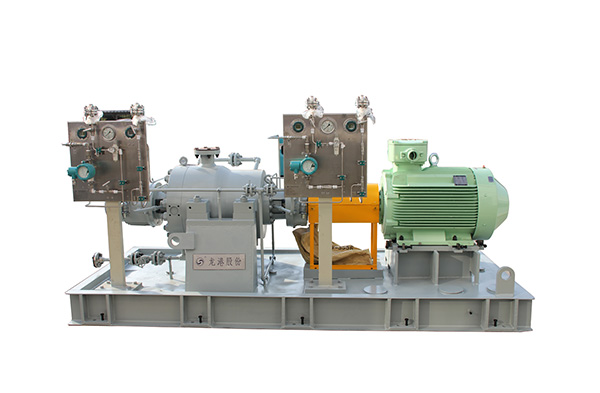

LTD (Type BB5) - Double-casing, radially split, multistage, between-bearings pump (barrel pump)

Power plant

Refinery plant

Petrochemical plant

Natural gas processing plants

Off-shore & on-shore platform water injection

Crude oil transferring

Main service: Hydrofeed pump, lean amine pump, water injection pump, coke cutting pump, etc.

Flange configuration conforms to ANSI / DIN / ISO standards

Mechanical seal chamber size conforms to ISO21049 (API682).

The rotors are designed in tandem or back to back structure

First stage double suction impeller or inducer structure can be used when operating at low NPSHa conditions

For large size pumps, entire internal parts can be removed with the bearing housing and the mechanical seal housing as a unit. The unit can be installed as a package after maintenance what can saving maintenance time

Depending on the conditions of power and axial force, self-lubricating and sliding bearing - thrust pad bearings are available,with additional lubricant system

Balanced drums or symmetrical impellers can be used to balance the axial forces

Capacity (Q): 5~1200 m3/h

Head (H): ~ 3000 m

Operating Pressure (P): ~ 30Mpa

Operating Temperature (T): -80℃~+450℃